Changli Electric has been actively involved in China's water conservancy construction and has made significant contributions to many water conservancy projects in China. Our company has developed TL and TLKS series vertical synchronous motors, which are the core driving equipment for water conservancy industry, by adopting advanced technology at home and abroad, through a mature and reliable design and production system, combined with our more than 70 years of experience in manufacturing medium and large high-voltage AC motors.

Product Overview

Changli Electric has been actively involved in China's water conservancy construction and has made significant contributions to many water conservancy projects in China. Our company has developed TL and TLKS series vertical synchronous motors, which are the core driving equipment for water conservancy industry, by adopting advanced technology at home and abroad, through a mature and reliable design and production system, combined with our more than 70 years of experience in manufacturing medium and large high-voltage AC motors. The TL and TLKS series vertical synchronous motors are the core driving equipment in water conservancy industry. Due to the high efficiency of synchronous motor, the anti-interference ability and stability are strong. They are mainly used to drive axial flow pumps, centrifugal pumps, inclined flow pumps, submersible pumps and other water conservancy engineering equipment.

Our company combines more than 70 years of manufacturing experience of medium and large high-voltage AC motors, adopts advanced technology at home and abroad, adopts mature and reliable design and production system, adopts new technology, new materials and new technology to continuously improve product design and manufacture, selects materials carefully and manufactures well, so that this series of products become more reliable operation, more compact structure, less vibration, lower noise, stronger outdoor application, lighter weight and higher efficiency. It is a mature product with more reliable operation, more compact structure, less vibration, lower noise, stronger outdoor application, lighter weight and higher efficiency.

This series of synchronous motor conforms to JB/T8667.2 "Technical condition of large three-phase synchronous motor part 2: TL series". The power level and installation size conform to our standard and IEC standard of International Electrotechnical Commission, and conform to German standard, and can be used as a supporting product for export equipment and a substitute product for imported products.

Technical Parameters

| Power range | 500~15000kW |

| Voltage | 6000V, 10000V |

| Speed | 375, 333, 300, 250, 214, 188, 167, 150, 136, 125r/min |

| Rated frequency | 50Hz or 60Hz |

| Frequency | 50Hz, 60Hz |

| Protection class | IP23, IP44, IP54 |

| Insulation class | F level (can also be assessed by B level) |

| Duty type | S1 |

| Cooling mode | IC01, IC81W |

| Installation | IM8421 |

| Standard | IEC,GB |

The performance indexes, installation and external dimensions of the outdoor (W), wet tropical zone (TH) and outdoor wet tropical zone (THW) motors derived from the series are the same as those of the basic series.

II. Advantageous features

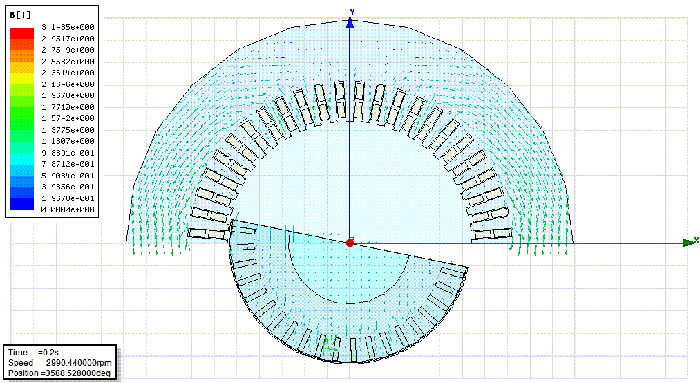

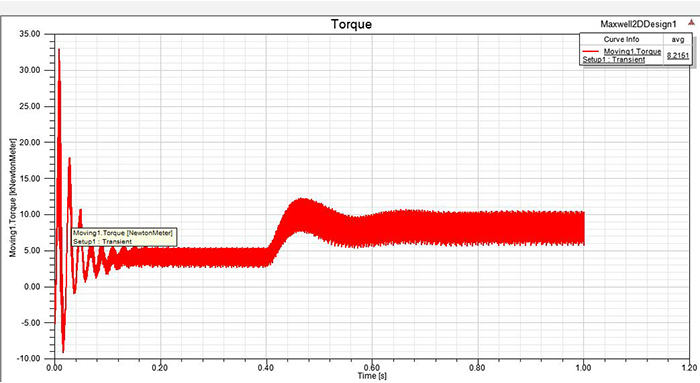

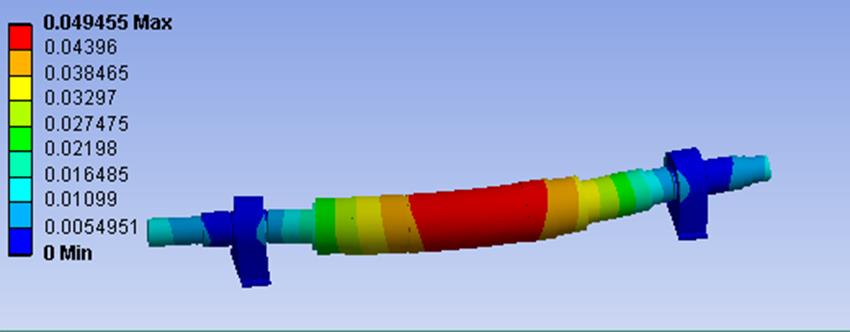

1. Advanced optimization design means

Combined with our long-term successful technology of producing medium-sized high-voltage motors, we adopt advanced design means to optimize the design of TL, TLKS series three-phase synchronous motors.

|  |

| Magnetic Field Analysis | Performance Analysis |

Shaft System Calculation

2. Reliable motor manufacturing technology

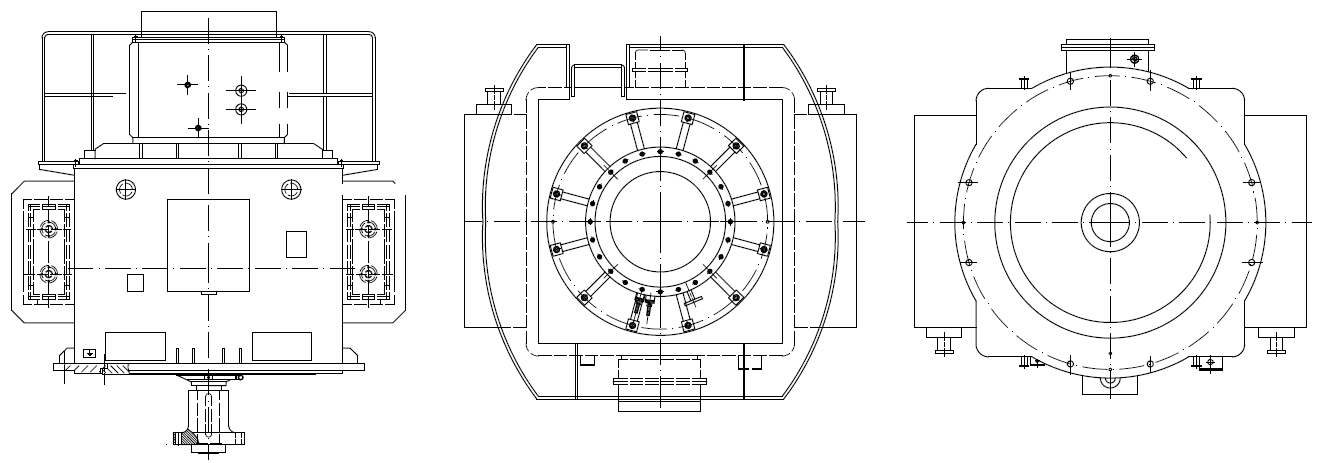

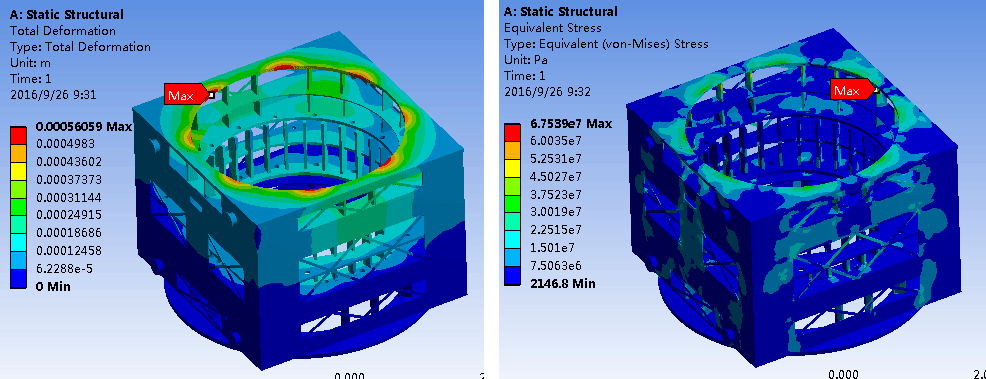

2.1 The machine base is made of box type structure with steel plate welded. In the axial direction, according to the function, there are ventilation, coil end, core cavity, and in the radial direction, the four corners of the seat are reinforced with through-length bent steel plate and the middle with through-length 50-thick rib plate, which has the advantages of good rigidity, strong support, strong torsional moment bearing and light weight. The upper and lower end plates and wall plates are thickened as necessary to improve the rigidity of the base and to provide good damping suppression when the motor vibrates.

2.2 The stator core is made of 0.5mm thick low-loss silicon steel sheets laminated with radial ventilation channels separating the core sections.

2.3 The stator winding is insulated with mica tape. After the winding is installed, vacuum pressure immersion paint (VPI) is applied to the whole stator, and the winding insulation grade is F, which has a good temperature rise margin. The coil slot fixing method and connection method of LDW advanced technology are introduced to ensure the long-term operation reliability of the motor.

2.4 The coil temperature measuring element, bearing temperature measuring element, vibration measuring probe, cooler water leakage detection device, etc. collect operating information at any time and deliver it to the control system exclusively to ensure that the motor is effectively monitored by the system.

2.5 The rotor shaft is made of forged steel with deep holes at the end, and the outer ring of the rotor bracket fixes the pole. Due to the vertical installation of the motor, a cantilever beam structure is formed between the pole and the bracket, and in order to prevent the bracket spoke plate from being bent by the gravity of the pole, braces are added on both sides of the spoke plate to change the force distribution of the bracket and enhance its tensile capacity.

2.6 pole core vertical installation, in the motor asynchronous start completed, the damping bar temperature decreases, and the gap between its installation with the hole becomes larger, by gravity, will occur loose string danger, coupled with the rotor in the process of rotation, the damping bar by the air gap high frequency harmonic oscillation, loosening the situation more serious. The project team has solved the loosening problem during the operation of the motor to a certain extent by tightening the damping bar and welding ferrules on the end of the damping bar to fix the damping bar and the core more tightly.

2.7 The excitation system includes excitation cabinet, brush holder, collector ring and excitation coil, connecting cable and cover. The rotor excitation cable is led out from the pole coil, thrown out through the deep hole of the rotor shaft to the upper part of the upper thrust bearing, and then connected to the collector ring conductive rod. The collector ring sleeve is connected to the rotor shaft through the end flange. The collector ring and brush rod holder are redesigned according to the variables of rotational speed, excitation capacity, and rotating shaft diameter, and the brush rod holder is fixed to the thrust bearing cover. The cover is round in shape and is mounted on the thrust bearing cover through the ring flange. The side of the cover has a waterproof connector, which is convenient for the excitation lead wire, and the front of the cover has a glass cover, which is convenient for the user to observe the operation status of the motor excitation system and to facilitate maintenance.

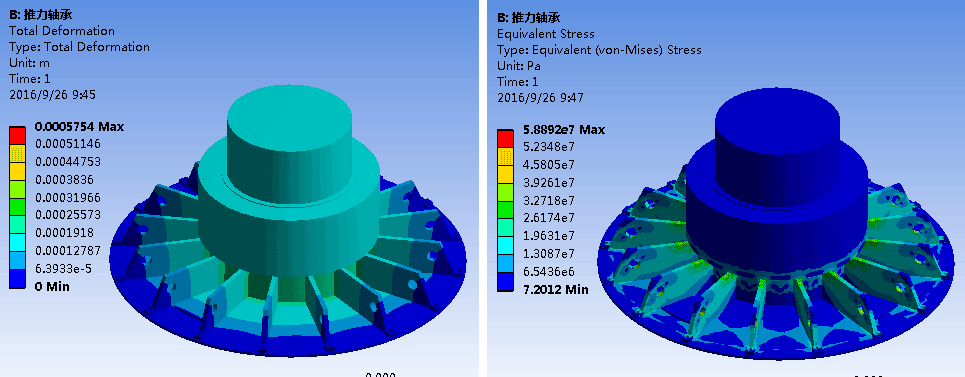

2.8 Synchronous vertical series motor has the characteristics of vertical installation and bearing axial force, according to the size of the applied load, the upper bearing adopts thrust bearing or plane thrust tile bearing respectively.

The thrust bearing is selected from the new domestic structure.

Features

(1) the use of advanced circular thrust tile structure, tile body using low carbon steel such as 20 steel surface casting tin-based pasteurized alloy, its use of disc spring support between the bearing plate, to achieve uniform distribution of thrust load between the tiles, can effectively absorb a variety of impact loads, its stability and impact resistance are better than the traditional rigid support tile bearings.

(2) The casting bearing box with heat dissipation rib makes the bearing unit with reliable rigidity, and its structure is more compact and beautiful in appearance.

(3) The oil-water cooler with double anti-leakage structure prevents oil leakage and water leakage, and the cooling and heat dissipation effect is significantly improved.