The current market for medium voltage motors (MVMs) within industrial automation is witnessing significant transformations driven by technological advancements and the need for greater efficiency. Manufacturers face challenges such as rising energy costs, increasing demand for sustainability, and the necessity for reliable performance in harsh environments. Solutions lie in adopting innovative medium voltage motor technologies that enhance operational efficiency while reducing overall lifecycle costs. For instance, implementing variable frequency drives (VFDs) with high-efficiency motors can lead to energy savings of approximately 30%, directly addressing these critical pain points.

Several key drivers are shaping the evolution of medium voltage motors in the automation sector. The shift towards Industry 4.0 is fostering the integration of digital technologies, such as IoT and machine learning, which optimize motor performance and predictive maintenance. According to a report by MarketsandMarkets, the global medium voltage motor market is projected to grow from USD 12.3 billion in 2022 to USD 16.8 billion by 2027, at a compound annual growth rate (CAGR) of 6.6%. This growth is largely influenced by innovations including:

High-Efficiency Designs: Advanced designs that comply with IEC 60034-30-1 regulations are improving energy efficiency, with some MVMs achieving efficiencies above 96%.

Smart Monitoring Systems: Integrated sensors allow real-time monitoring and diagnostics, potentially reducing downtimes by up to 20%, as per a study by the International Energy Agency.

Modular Motor Systems: These allow for customizable solutions that can be easily scaled and maintained, enhancing overall operational flexibility and up-time.

As the landscape of automation evolves, several emerging trends in medium voltage motors are worth noting:

Decarbonization Efforts: With industries increasingly focused on reducing carbon footprints, medium voltage motors designed for eco-friendliness are seeing a rise in demand. An analysis from the Environmental Protection Agency indicates that energy-efficient motors can cut energy consumption by 2.4 million megawatt-hours annually.

Integration with Renewable Energy Sources: More facilities are leveraging renewable energy, which requires adaptable motor systems. According to research by the National Renewable Energy Laboratory, integrating MVMs with solar and wind energy systems can increase sustainability while saving costs by up to 20%.

Cybersecurity Measures: The rise of connected devices demands enhanced cybersecurity protocols, with a recent Cybersecurity & Infrastructure Security Agency report stating that 30% of industrial cybersecurity incidents involve unauthorized changes to automation settings, highlighting the need for secure medium voltage motor control systems.

As these trends continue to evolve, buyers are faced with transformative impacts on their purchasing decisions. The focus on sustainability is not only providing cost-saving opportunities but also reshaping how MVMs are evaluated. Companies are increasingly prioritizing energy efficiency, reliability, and the compatibility of motors with modern automation systems. The comprehensive total cost of ownership (TCO) analysis reveals that organizations can save up to 15% over a 10-year lifecycle by selecting high-efficiency motors equipped with smart technology from reliable manufacturers like CHANGLI ELECTRIC MOTOR.

To fully capitalize on these trends and advancements in medium voltage motor technology, organizations should consider the following practical strategies:

Conduct thorough energy audits to assess current motor systems and identify areas for improvement.

Engage with reputable providers like CHANGLI ELECTRIC MOTOR to explore innovative motor solutions tailored to specific industry needs.

Implement training programs for employees focused on the operation and maintenance of new digitalized motor systems.

Stay informed about industry standards and regulations that impact motor efficiency and compliance.

What are medium voltage motors used for?

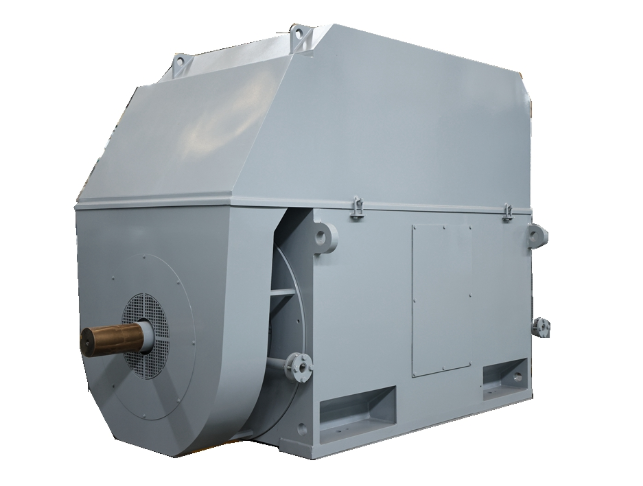

Medium voltage motors are used extensively in industrial applications such as pumps, compressors, fans, and conveyors, operating typically between 1kV and 15kV.

How do medium voltage motors improve energy efficiency?

By utilizing advanced technologies like VFDs and high-efficiency designs, medium voltage motors can significantly reduce energy consumption, leading to lower operational costs.

What maintenance practices are essential for medium voltage motors?

Regular inspections, monitoring of operating conditions, and timely maintenance procedures (like lubrication and alignment checks) are critical for assuring optimal performance and reliability.