Y2HV series high-voltage three-phase asynchronous motor (frame size 355~630mm) introduce German technology, combined with our company's experience in producing high-voltage explosion-proof motors, adopt new technology, new materials, carefully selected materials, manufacture the high-efficiency motors. The motors are characterized by more reliable operation, more compact structure, lower vibration, less noise, outdoor application, lighter weight, and the efficiency reaches the national Class 3 energy efficiency standard. It is suitable for hazardous places in Zone 1 and Zone 2 with explosive gas environment. As a prime mover, it can be widely used in mining, machinery industry, petrochemical industry, power plant and other industries for driving various general machinery, such as, compressors, pumps, crushers, winches, centrifuges, scrap shredders, cutting machines, belt conveyors, transport machinery, etc. It is the ideal driving equipment.

Product Overview

Y2HV series high-voltage three-phase asynchronous motor (frame size 355~630mm) introduce German technology, combined with our company's experience in producing high-voltage explosion-proof motors, adopt new technology, new materials, carefully selected materials, manufacture the high-efficiency motors. The motors are characterized by more reliable operation, more compact structure, lower vibration, less noise, outdoor application, lighter weight, and the efficiency reaches the national Class 3 energy efficiency standard. It is suitable for hazardous places in Zone 1 and Zone 2 with explosive gas environment. As a prime mover, it can be widely used in mining, machinery industry, petrochemical industry, power plant and other industries for driving various general machinery, such as, compressors, pumps, crushers, winches, centrifuges, scrap shredders, cutting machines, belt conveyors, transport machinery, etc. It is the ideal driving equipment.

In the field of drive technology, we always pursue the development goals of high efficiency, energy conservation, environmental protection, smaller size, higher power, higher efficiency and more reliable performance.

The power and installation size of this series of motors conform to Chinese standards and IEC standards of International Electrotechnical Commission, and conform to German standards, and can be used for the matching of overseas equipment and the replacement products of imported equipment.

Advantageous Features

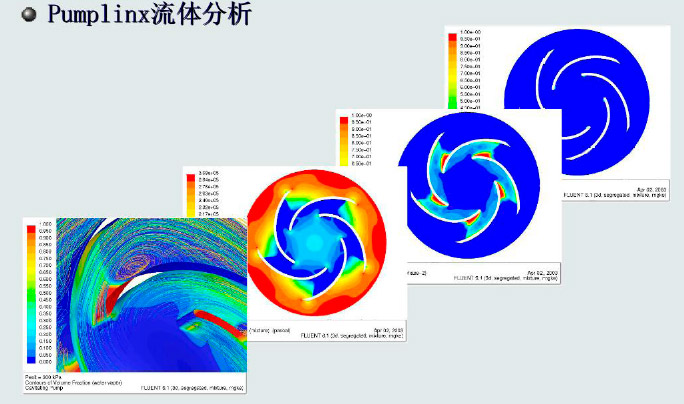

1. Advanced optimization design means

Combined with our long-term successful technology of producing medium-sized high-voltage motors, we adopt advanced design means to optimize the design of YB series high-voltage high-efficiency explosion-proof three-phase asynchronous motor.

|  |

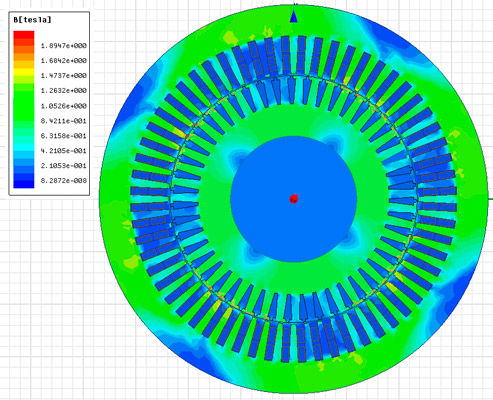

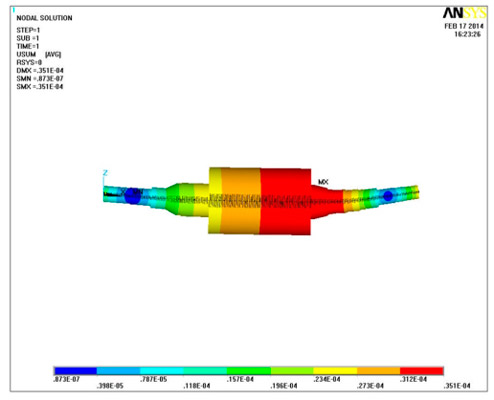

| Electromagnetic analysis diagram using the "field and circuit " combination method | Axial system analysis diagram |

2. Worry-free mechanical structure

Frame base: The motor base and end cover are made of high-strength gray cast iron with mature technology, or ductile iron can be used in more severe environment. The thickened base wall, box design base end structure and foot structure make the frame have higher strength and rigidity. Horizontal and vertical heat sink cast iron base is used in the housing, and four axial ventilation channels are provided inside the chassis, and horizontal and vertical heat sink bars are distributed inside the chassis corresponding to the winding end positions to increase the internal heat sink area. The junction box is installed at the ventilation channel on the side of the motor, and two angle-adjustable lifting rings are placed diagonally on the ventilation channel.

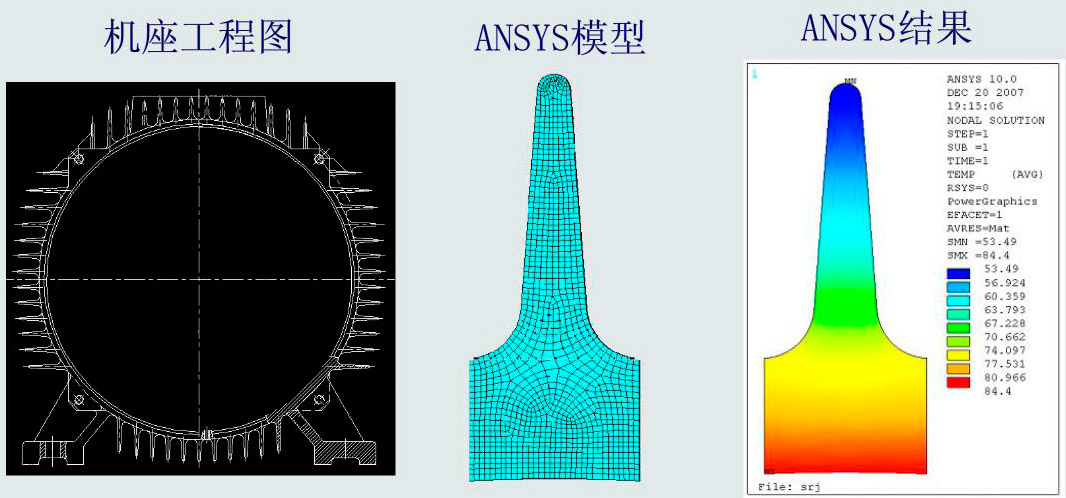

Y2HV motor frame

ANSYS analysis of the application of cast iron base heat sink temperature field calculation

3. Efficient cooling system

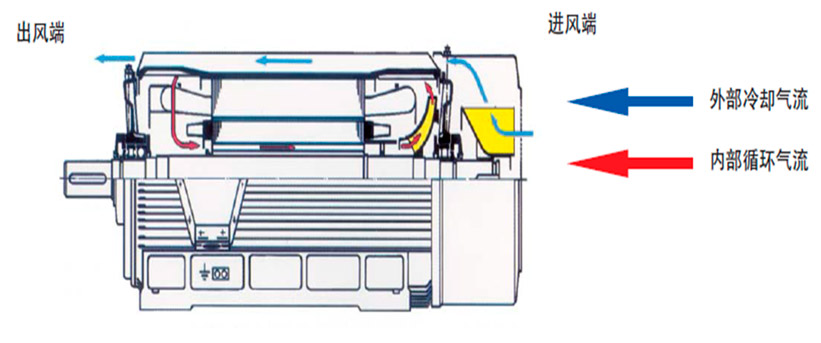

The motor is designed with separate external cooling air circuit and internal cooling air circuit to achieve the maximum cooling effect with the minimum loss. The heat generated by the stator of the motor is mainly transferred from the stator core to the machine base and then taken away by the external cooling airflow; the heat generated by the rotor and stator winding ends is transferred from the internal cooling circuit to the machine base.

The cooling airflow of the external cooling air circuit blows through the cooling rib of the chassis and flows along the cooling rib from the non-driving end to the driving end. The aerodynamic design of the cooling rib of the chassis enables the airflow to achieve high cooling efficiency; the junction box is installed far away from the cooling rib, which has no obstruction to the airflow; the inner cooling rib is provided on the inside of the chassis around the stator winding end to fully dissipate the heat.

The internal cooling air circuit makes the air flow through the rotor ventilation holes through the internal fan, so that the internal heat is continuously conducted to the machine base and the end cover, and the machine base plays the role of internal and external air heat exchanger; the cooled air is returned in the same direction as the external cooling air through the four ventilation pipes inside the machine base for sequential cooling, so that the heat dissipation of the motor is uniform.

Double circuit cooling not only achieves higher power density of the motor, but also ensures uniform temperature distribution in the motor.

Motor external internal cooling air path

Internal cooling system simulation

4. Proven VPI vacuum pressure impregnation technology

The insulation system used in our high-voltage motors is proven for many years, combined with the introduced technology, the new technology of modern process, and gradually increase the proportion of mica, this insulation system is still developing and improving. The stator winding adopts 155(F) grade insulation, with reliable fixing and tying at the coil end, and it has been tested by several inter-turn pulse voltage tests and voltage resistance tests to ground during the manufacturing process, and treated by VP worker vacuum pressure impregnation solvent-free process, which has high electrical strength, mechanical strength and good corrosion resistance and moisture resistance. The coil core is treated with special anti-corona treatment, so that the motor can operate safely in areas with high altitude.

5. Reliable bearing structure

The motor is equipped with non-stop oiling and draining devices at both ends for regular grease replenishment, stator and bearing temperature measuring and anti-condensation heating devices inside the motor, and bearing temperature measuring instruments or stator temperature measuring instruments can be installed to monitor the bearing or stator temperature on site according to users' needs.

6. Reliable squirrel cage rotor structure

The motor usually adopts cast aluminum rotor. Using centrifugal casting process or die-casting process, liquid pure aluminum is poured into the rotor core groove and cast into shape at one time, and the rotor guide bar and end ring are cast into a whole. The cast aluminum rotor structure and process ensure the incomparable reliability of the motor rotor, while making the motor have satisfactory torque characteristics. Large-capacity motors use copper bar rotors; reliable guide bar fastening and end ring welding processes, as well as the ring guard structure of high-speed motors, ensure the reliable operation of copper bar rotors.